Products Detail Technical Parameter Feature And Application Fields Of Use Details Download

1. High temperature differential thermal analyzer introduction

Instrument innovation:

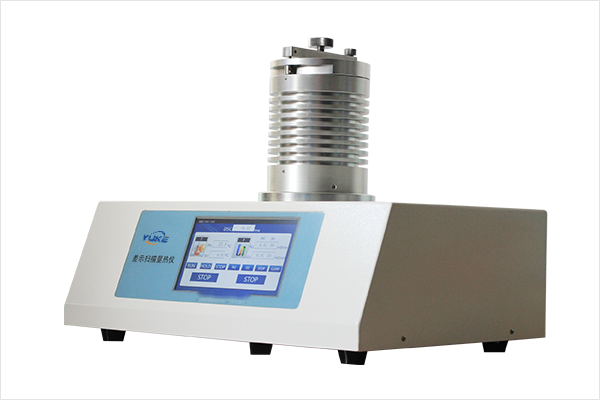

The furnace body adopts an open-top structure, which replaces the traditional lifting furnace body, with high precision and easy operation.

2. High temperature differential thermal analyzer parameter

Model | YK-DTA3320 |

Temperature range | Room temperature~1150℃ |

Measuring range | 0~±2000μV |

DTA accuracy | ±0.1μV |

Heating rate | 1~80℃/min |

Temperature resolution | 0.1℃ |

Temperature accuracy | ±0.1℃ |

Temperature repeatability | ±0.1℃ |

Temperature control | Heating up: program control, parameter adjustment can be carried out according to needs; |

Cooling down: air cooling, program control |

Constant temperature: program control, constant temperature time can be set arbitrarily |

Furnace structure | The furnace body adopts an open-top structure, which replaces the traditional lifting furnace body, with high precision and easy operation |

Atmosphere control | Automatic switching of internal programs |

Data interface | Standard USB interface, supporting data cable and operating software |

Host display | 24bit color, 7 inch LCD touch screen display |

Parameter standard | Equipped with standards, with one-key calibration function, users can calibrate the temperature by themselves |

Baseline adjustment | Users can adjust the baseline through the slope and intercept of the baseline |

Power supply | AC 220V 50Hz |

3. High temperature differential thermal analyzer feature and application

1: The main control chip of the High temperature differential thermal analyzer adopts the Cortex-M3 core ARM controller, which has faster processing speed and more precise temperature control.

2: Using USB two-way communication, the operation is more convenient.

3: Using 7-inch 24bit color full-color LCD touch screen, the interface is more friendly.

4: The platinum rhodium alloy sensor is used, which is more resistant to high temperature, corrosion and oxidation.

4. Fields of use High temperature differential thermal analyzer

High temperature differential thermal analyzer has a wide range of applications, especially in the research and development, performance testing and quality control of materials.

5. Product qualification

Yuke High temperature differential thermal analyzer has obtained CE certification, TART certification, ISO quality management system certification, more than 10 software copyrights and multiple patents to ensure that each instrument has stable performance and excellent quality.

Download

keyword search:DTA Differential Thermal Analyzer

INQUIRY

INQUIRY